DHX Coal Fired CFB Steam Boiler

- Type:Steam Boiler

- Capacity:35-75 t/h

- Pressure:1.25-5.3 MPA

- Fuel:Bituminous coal, anthracite, meagre coal, biomass, lignite, gangue, waste, sludge

- Application:Chemical, food, tobacco, textile, printing and dyeing, feed, medicine, building material, wine, rubber, hospital

Overview

Brief Introduction:

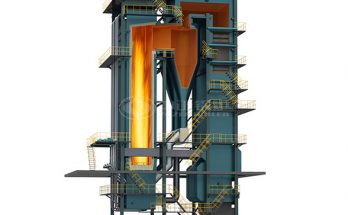

As a new mature high-efficiency and low-pollution clean coal technology, circulating fluidized bed combustion (CFBC) technology has many advantages that other combustion methods do not have. Circulating fluidized bed combustion is low-temperature combustion, so the NOx emission is much lower than that of pulverized coal furnace, only 200ppm. CFBC can desulfurize directly during the combustion process, and the desulfurization efficiency is high. The technology and equipment are simple and economic, and the costs of its initial investment and operation are much lower than those of dry pulverized coal furnace and flue gas desulfurization (PC+FCD). The discharged ash residue has good activity and is easy to be comprehensive utilized without secondary ash residue pollution. The load adjustment range is large, and the low load can be reduced to about 30% of the full load.

Features

-

High combustion intensity and small cross section area: The high heat load of furnace section area is another main advantage of CFB boiler. The heat load of the section is about 3.5 ~ 4.5MW/m2, close to or higher than that of the pulverized coal boiler. Under the same heat load, the cross-sectional area of the furnace needed by the bubbling fluidized bed boiler is 2-3 times larger than that of the circulating fluidized bed boiler.

-

High combustion efficiency: The combustion efficiency of circulating fluidized bed boiler is higher than that of bubbling fluidized bed boiler, which can be compared with pulverized coal boiler in the range of 95-99%. The high combustion efficiency of CFB boiler is due to the following feature: good gas-solid mixing; high combustion rate, followed by fly ash recycling combustion.

-

The range of load regulation is large, and load regulation is fast: When the load changes, only the amount of coal, air and material circulation needs to be adjusted, and the separate-bed fire-pressing technology is not needed as the bubble fluidized bed boiler does. Also, unlike coal pulverized boilers, oil should be fired at low load to maintain stable combustion. Generally speaking, the load ratio of circulating fluidized bed boiler can reach (3~4):1. The load regulation rate is also very fast, usually up to 4% per minute.

Quick Way To Get Price

Please feel free to fill in the following form or email us (zhulin@zozen.com) to get product information,price,service and other supports.We will reply to you within 24 hours as soon as possible. Thank You!